Joined forces! Dinglong officially launched the ICMtia joint analysis, testing and technical cooperation service platform

- Categories:Company dynamics

- Author:

- Origin:

- Time of issue:2020-05-12

- Views:0

(Summary description)From May 11, 2020, the joint analysis, testing, and technical cooperation service platform (hereinafter referred to as the service platform) has been officially put into use on the official website of ICMtia (Integrated Circuit Material Industry Technology Innovation Alliance).

Joined forces! Dinglong officially launched the ICMtia joint analysis, testing and technical cooperation service platform

(Summary description)From May 11, 2020, the joint analysis, testing, and technical cooperation service platform (hereinafter referred to as the service platform) has been officially put into use on the official website of ICMtia (Integrated Circuit Material Industry Technology Innovation Alliance).

- Categories:Company dynamics

- Author:

- Origin:

- Time of issue:2020-05-12

- Views:0

From May 11, 2020, the joint analysis, testing, and technical cooperation service platform (hereinafter referred to as the service platform) has been officially put into use on the official website of ICMtia (Integrated Circuit Material Industry Technology Innovation Alliance).

(Click "Read the original text" at the bottom of the article to go directly to the platform page)

The service platform is a professional service platform led by the Materials Alliance and actively participated in the construction of many co-construction units. The service platform focuses on collecting and publishing resources such as instruments and equipment belonging to the alliance members in order to promote the technological innovation and development of the domestic semiconductor industry.

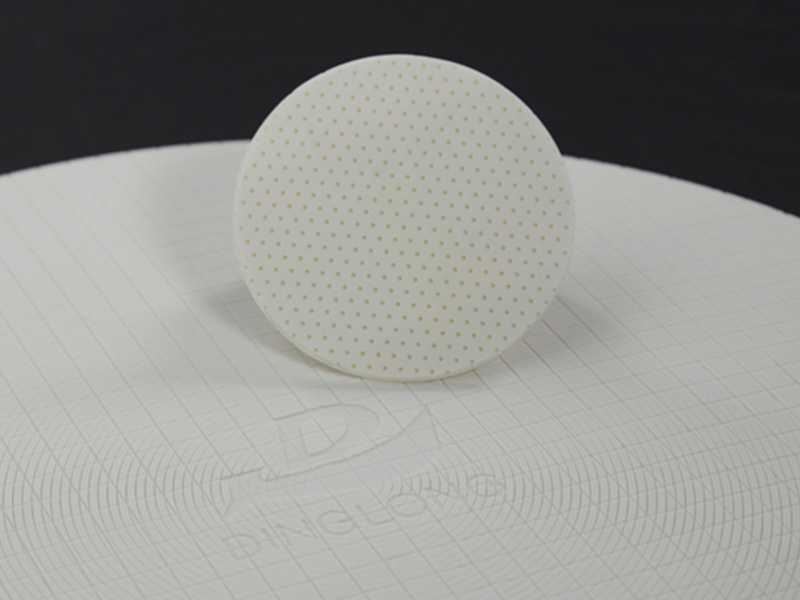

Dinglong, as a leading enterprise in the field of CMP polishing pads in China, and a member unit of the material alliance, its holding subsidiary Hubei Dinghui Microelectronics Materials Co., Ltd. actively responded to this.

Hubei Dinghui Microelectronics Material Co., Ltd. is the only domestic supplier of full-process CMP polishing pads, the only domestic manufacturer with key casting process technology, an international R&D and production team, and world-class advanced imported production Equipment, high-standard dust-free production workshops and the only domestic 200mm and 300mm CMP Pad evaluation laboratory have built an automated CMP polishing pad industrial production line synchronized with the top international manufacturers. The company has strong independent research and development, innovation and engineering industrialization capabilities. The products are applicable to Oxide, W, Cu bulk, and CMP Pad applicable to Barrier; at the same time, the company has strong customization capabilities and can be customized according to customer needs Develop products suitable for their special needs.

|

01 12 inches Chemical mechanical grinding machine AMAT 300 CMP |

|

|

Perform chemical mechanical polishing on 12-inch wafers. |

|

|

02 Rice KLA P-7 |

|

To 8 inch/12 inch wafer dishing/erosion Perform testing. |

|

03 AFM |

|

|

To 8 inch/12 inch The topography of the wafer surface is scanned. |

|

|

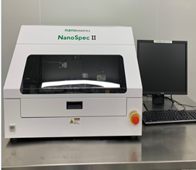

04 nano spec Ⅱ |

|

To 8 inch/12 inch The oxide wafer thickness is measured. |

|

05 napson RG-300 |

|

|

To 8 inch/12 inch copper/tungsten wafer the thickness is measured. |

|

|

06 AMAT 300 SEM review |

|

Review the defects of 12-inch wafers. |

|

07 KLA 300 SP2 |

|

|

Defect inspection on 12-inch wafers |

|

|

08 8寸 化学机械研磨机台 MAT 200 CMP |

|

Perform chemical mechanical polishing on 8-inch wafers. |

Scan the QR code to read on your phone

Related News

Hubei Dinglong Holdings Co., Ltd. All rights reserved 鄂ICP05005497-2

Powered by www.300.cn wuhan2